KØBENHAVNS ERHVERVSAKADEMI

Individual Thesis Research and Year-Long Installation

YEAR: April 2018-Present

ADDRESS: 29N Guldbergsgade, 2200 København N

SUPERVISORS: Mette Marko Hansen, Anke Pasold (Material Design Lab KEA)

SUPPORT: KEA Campus Service (September 2018), Boligfonden Spirekasse (March 2019

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

PROJECT DESCRIPTION: Imagine a building material that is rot resistant, fire resistant, non-toxic, insulates comparably with mineral wool, and can be used to create carbon negative buildings. Sounds amazing, right? Actually, this material has been used for centuries already around the world- until we forgot how to use it. It’s called eelgrass, and is a type of seagrass.

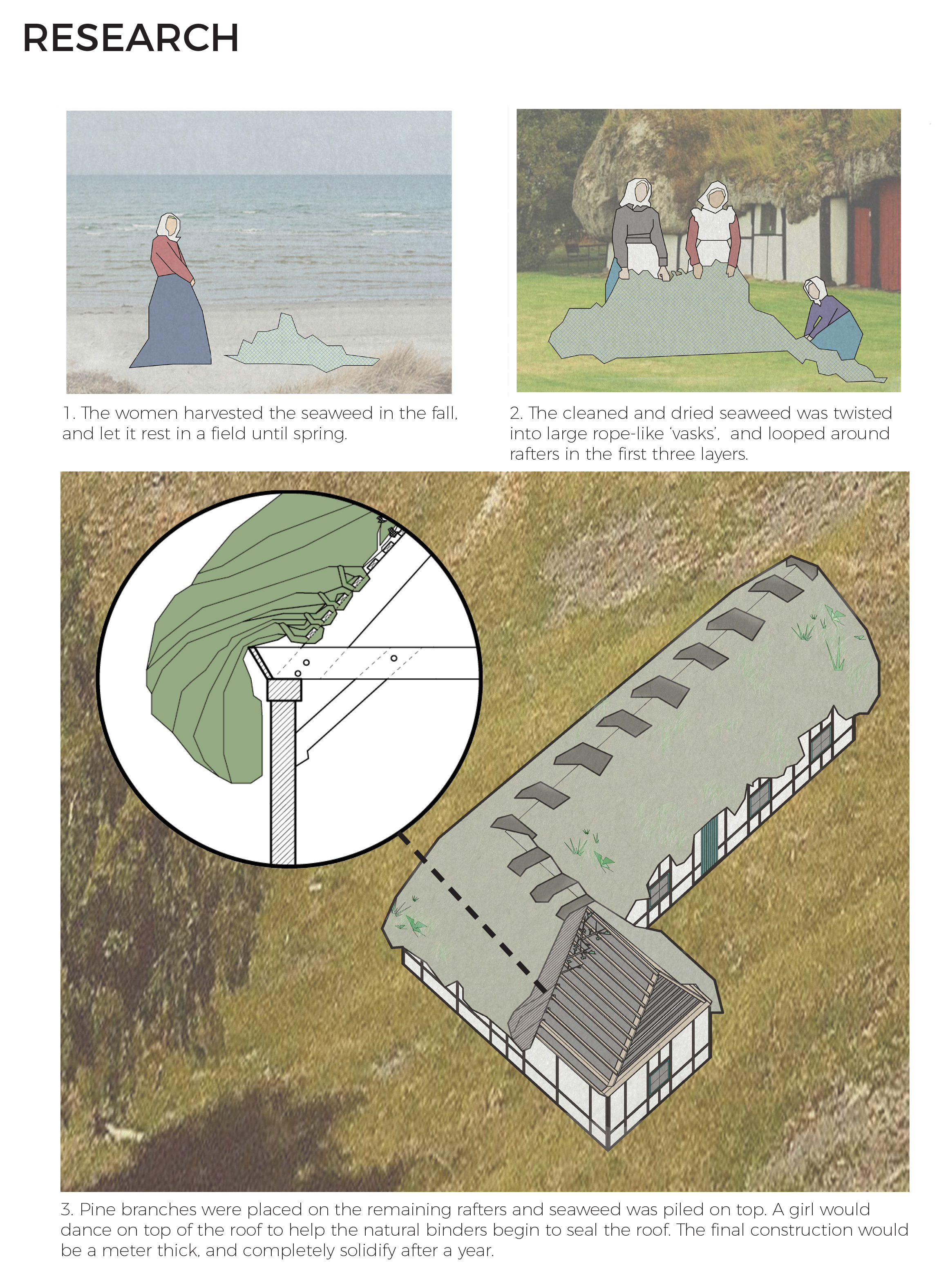

I chose to focus my thesis on the seaweed houses of Læsø, as it is a subject without many resources in English, and has huge potential for the global building industry. In the middle ages, on Læsø they began to build thatched eelgrass roofs after running out of timber on the island. Eelgrass grows across the world, but has declined in amount due to climate change and a wasting disease in the 1930s, and the thatching method on Læsø was nearly lost as a result.

Eelgrass has an incredible potential as a world-wide building material. As a result, I chose not only to focus on the historical context of the seagrass, but current and future applications of it.

Concept AutoCAD Drawings

Installation Video

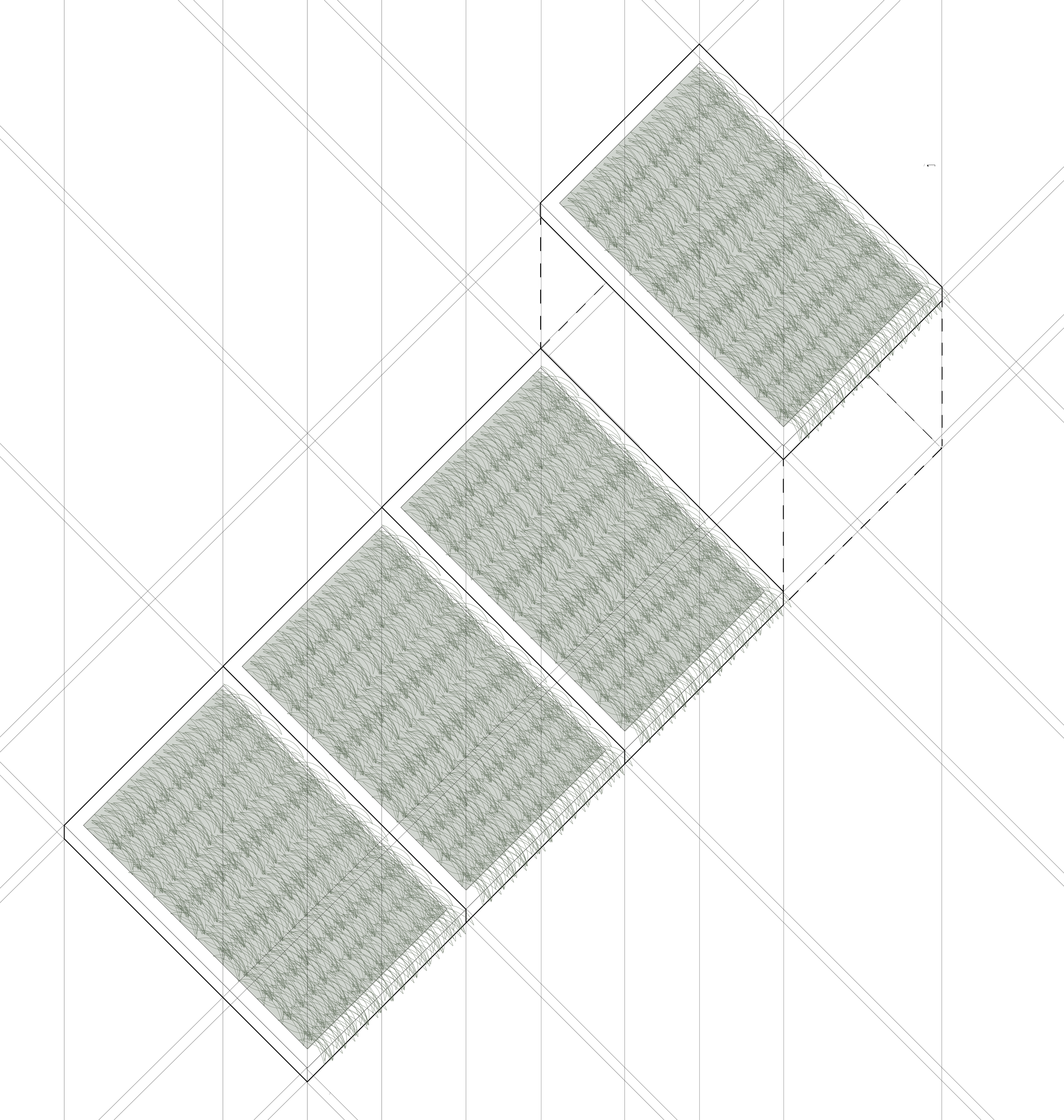

It is not a requirement for the thesis to conduct original research. However, I decided to expand on my previous finalist competition entry and develop a prefabricated panel that could be used for roof or facade externally.

These panels, along with the small scale tests, will be installed on a structure on the roof terrace of Guldbergsgade 29N for a year to study how the eelgrass reacts over time to the elements, as well as the thatch construction that I have created.

The installation will continue even after the thesis submission in October 2019. The panels were designed with the original tectonics of the Læsø houses in mind: embracing the organic quality of the material instead of forcing it to conform. However the wood boundaries and underlying structure of the panels transforms the tectonics, adding repetition and order to the organic properties of the seaweed.

Photo by Anders Lorentzen, KEA Communications

Invitation by Material Design Lab

Photo by Anders Lorentzen, KEA Communications

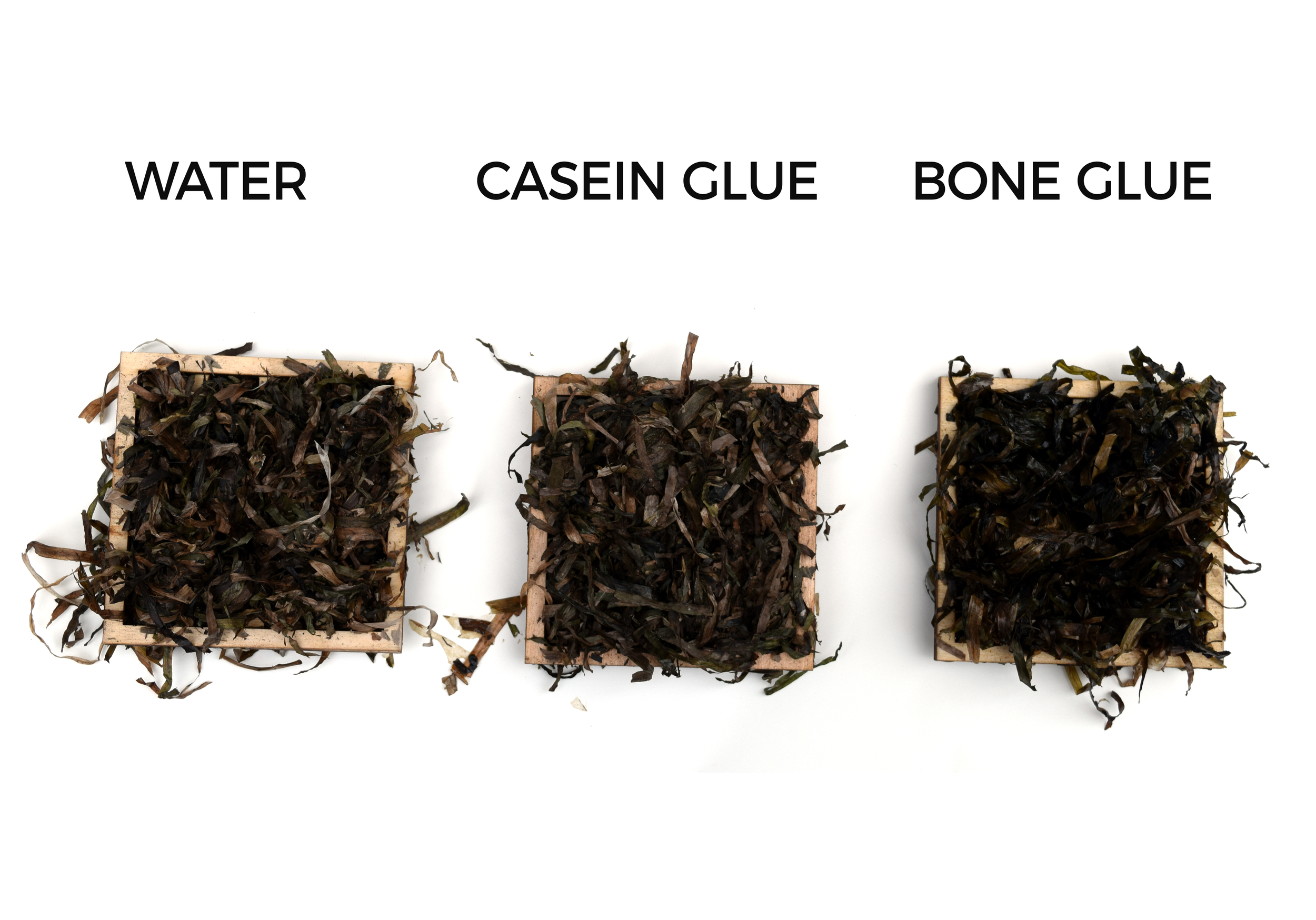

I began with small-scale tests, building off both the old methods of thatching, and existing research from Studio Seagrass and Tobias Gumstrup Lund Øhrstrøm's master thesis. Tobias combined eelgrass with different natural binders, which in some cases made it immediately waterproof, and also created a structural integrity.

These small scale tests consisted of first working only with water and eelgrass, rehydrating the eelgrass, and then adding minimal amounts of natural binders, on 10x10cm structured wood panels. Since the goal was to retain the organic quality of the eelgrass, very minimal amounts of binder were used in the mixtures and recorded meticulously to account for human error and variety. I only used natural binders, so that the non-toxicity of the eelgrass would be preserved.

I started with two natural binders and water. I expanded to eight different binders that were plant or animal based with different bloom strengths. Three of each binder and panel typology were made in these sketch models to be installed on varying sides of the installation structure.

After the small scale tests, I decided to make the larger panels out of just water and eelgrass. This is because in general the binders changed the texture and the nature of the eelgrass, removing it from its original context.

The water allowed flexibility in the eelgrass while thatching, while the binders stiffened and in some cases made the eelgrass more brittle. However the binders could improve the water-tight abilities of the construction and studying it outside over time will allow me to research this.

Photo by Anders Lorentzen, KEA Communications

In March 2019, I received a scholarship from Boligfonden Spirekasse to continue researching and developing my panels for the building industry.

PRESS AND ARTICLES

KEA Nyheder (Danish)

Boligfonden Spirekasse (Danish)

Dezeen (English)

Web Magazine Axis (Japanese)

Disup (Spanish)

Material District (English)

Haeckels (English)

EcoNoticias (Spanish)

MaterialConneXion Italia (Italian)

Materials World Magazine (English)

GeniusLoci Architettura (Italian)

Innovatieve Materialen (English/Dutch)

Archi.ru (Russian)

Pro Remont (Russian)

Design Indaba (English)